Biological Treatment

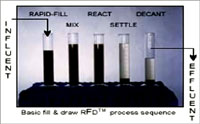

Sequencing Batch Reactors (SBR)

The Sequencing Batch Reactor (SBR) is an activated sludge process designed to operate under non-steady state conditions. An SBR operates in a true batch mode with aeration and sludge settlement both occurring in the same tank.

The operating principles of a batch activated sludge process, or SBR, are characterized in five periods:

- Fill

- React

- Settle

- Decant

- Idle

Activated Sludge

Activated sludge is a process dealing with the treatment of sewage and wastewaters. Atmospheric air or pure oxygen is bubbled through primary treated sewage (or industrial wastewater) combined with organisms to develop a biological floc which reduces the organic content of the sewage.

Membrane Bio Reactors (MBR)

Membrane Bio Reactor is a combination of process like microfiltration or ultrafiltration with a suspended growth bioreactor.

MBR process could produce effluent of high quality enough to be discharged to coastal, surface or brackish waterways or to be reclaimed for urban irrigation. Other advantages of MBRs over conventional processes include small footprint, easy retrofit and upgrade of old wastewater treatment plants.

Hybrid System

If the wastewater stream of a wastewater treatment plant is treated both conventionally and with a membrane filtration, the combination is called a Hybrid System. The system can consist of either two parallel systems with individual biological treatment steps, or of a common aeration step with split biomass separation, which is effected by conventional treatment and membrane filtration. Hybrid Systems are particularly suited for upgrades or capacity increases of existing conventional plants. The only investment necessary (compared to a completely new plant) are the costs for treatment of the additional hydraulic or organic load. Further advantages are the low footprint requirements and the productions of high-quality process water for many re-use applications.

Anaerobic Systems

Anaerobic biological wastewater treatment systems are widely used in strong organic wastewater treatment.